During the 2025 M2i Conference at Papendal, Anton Gorter of Civiele Technieken de Boer presented the progress of SUBLIME’s field monitoring work on the Van Hall Bridge in Amsterdam. His talk, “An on-site measurement campaign – it sounds so simple” highlighted the many practical steps and unforeseen challenges involved in collecting high-quality strain data on a historic movable steel bridge.

The Van Hall Bridge, a steel movable bridge dating from 1931, serves as one of the key field testing locations within SUBLIME. Although the central question sounded straightforward—can strain measurements be performed on the bridge?—the process revealed how many decisions and preparations stand behind a single monitoring campaign. Working with the SUBLIME research teams, the engineering company Arup first identified the fatigue-sensitive details that required attention: the main girders, affected by opening and closing cycles, and the front cross-girder, which experiences bending from traffic. With these targets defined, the team developed a detailed measurement plan covering sensor types, positions, cable routing, and coordinated data acquisition at 1000 Hz.

Challenges Beneath the Surface

Much of the work took place in conditions that standard engineering drawings never show. The bridge is accessible only from the water, located on a busy Amsterdam shipping route, which required installation teams to work from a boat and pontoon under strict safety measures. Multiple permits had to be arranged—covering waterway use, environmental conditions, traffic measures, and entry into the bascule cellar. Even gaining access to the cellar was a process of its own, as Amsterdam protects the keys to its bridges with great care.

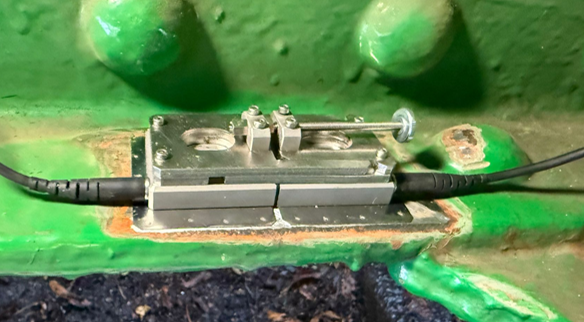

Installation under and inside the steel structure by CT de Boer demanded precise workmanship. Sensors, provided by SUBLIME partner Somni, had to be pre-tensioned and welded into place, portions of the coating removed and restored, and delicate fibre-optic lines protected in an exposed outdoor environment. The interrogator, power supply, and logging equipment were installed in the cellar to allow continuous monitoring at high frequency. Any deviation from the planned layout, even a few centimetres, required coordination with the researchers to ensure the data would remain meaningful.

A Three-Part Test Campaign

After installation, the team carried out a structured series of measurements. The first stage involved controlled truck loading: a 30-tonne truck with known axle weights crossed the bridge at speeds from 10 to 40 km/h. This was followed by five weeks of continuous monitoring under normal traffic conditions, capturing thousands of daily load cycles. Finally, two full opening cycles of the bridge were recorded, including measurement of the deck angle to link movement to stress development. All measurements were collected at 1000 Hz. By the end of the campaign, more than 2 terabytes of data were gathered. CT de Boer and Somni are now preparing these datasets for analysis, after which they will support fatigue modelling at Eindhoven University of Technology and contribute to the Digital Twin development at the University of Twente.

Building Reliability Through Measurement

Anton concluded his talk by emphasizing that reliable assessment begins with reliable measurements. The Van Hall Bridge campaign shows how SUBLIME’s scientific and modelling work relies on precise, carefully planned field activities carried out on real, operational structures. This combination of practical engineering and academic research helps advance the understanding of fatigue behavior in movable bridges and supports the broader goal of improving the long-term reliability of Dutch steel infrastructure.

Bridges to a Circular Society

We are excited to announce the publication of Karel Van den Berghe on circular economy strategies for large steel structures, part of the SUBLIME project. It is now available on “De Lichtkogel.nl,” delve into sustainable practices for infrastructure, focusing on the lifecycle extension of steel bridges through innovative technologies and design. This publication marks a significant step towards integrating circularity into infrastructure planning.

In Memoriam: Professor Paul Havinga

We are deeply saddened to announce the unexpected passing of Prof. Dr. Ing. Paul Havinga on May 3, 2024. A distinguished figure in computer science, Professor Havinga was a cornerstone of the University of Twente’s Pervasive Systems group and a driving force within the SUBLIME project. His leadership in Work Package 2, focusing on the development of a data platform and digital twins for steel infrastructures, was instrumental in advancing the project’s objectives.

First Annual meeting and Lunching of SUBLIME video

At our Annual project meeting, hosted by ARUP on March 22, 2024, we launched a new phase for the SUBLIME project. This project is all about using smart technology and engineering to make big steel structures like bridges and buildings stronger and last longer. We’re focusing on beating two big problems: fatigue and corrosion, with something called Structural Health Monitoring.