During the 2025 M2i Conference at Papendal, Anton Gorter of Civiele Technieken de Boer presented the progress of SUBLIME’s field monitoring work on the Van Hall Bridge in Amsterdam. His talk, “An on-site measurement campaign – it sounds so simple” highlighted the many practical steps and unforeseen challenges involved in collecting high-quality strain data on a historic movable steel bridge.

The Van Hall Bridge, a steel movable bridge dating from 1931, serves as one of the key field testing locations within SUBLIME. Although the central question sounded straightforward—can strain measurements be performed on the bridge?—the process revealed how many decisions and preparations stand behind a single monitoring campaign. Working with the SUBLIME research teams, the engineering company Arup first identified the fatigue-sensitive details that required attention: the main girders, affected by opening and closing cycles, and the front cross-girder, which experiences bending from traffic. With these targets defined, the team developed a detailed measurement plan covering sensor types, positions, cable routing, and coordinated data acquisition at 1000 Hz.

Challenges Beneath the Surface

Much of the work took place in conditions that standard engineering drawings never show. The bridge is accessible only from the water, located on a busy Amsterdam shipping route, which required installation teams to work from a boat and pontoon under strict safety measures. Multiple permits had to be arranged—covering waterway use, environmental conditions, traffic measures, and entry into the bascule cellar. Even gaining access to the cellar was a process of its own, as Amsterdam protects the keys to its bridges with great care.

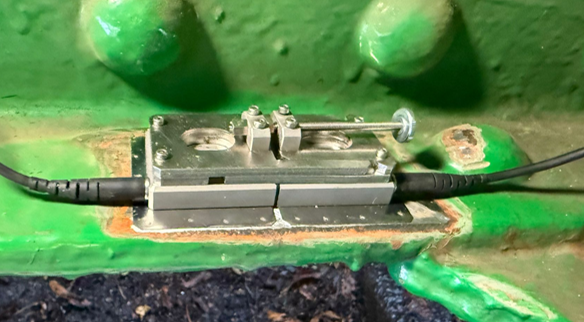

Installation under and inside the steel structure by CT de Boer demanded precise workmanship. Sensors, provided by SUBLIME partner Somni, had to be pre-tensioned and welded into place, portions of the coating removed and restored, and delicate fibre-optic lines protected in an exposed outdoor environment. The interrogator, power supply, and logging equipment were installed in the cellar to allow continuous monitoring at high frequency. Any deviation from the planned layout, even a few centimetres, required coordination with the researchers to ensure the data would remain meaningful.

A Three-Part Test Campaign

After installation, the team carried out a structured series of measurements. The first stage involved controlled truck loading: a 30-tonne truck with known axle weights crossed the bridge at speeds from 10 to 40 km/h. This was followed by five weeks of continuous monitoring under normal traffic conditions, capturing thousands of daily load cycles. Finally, two full opening cycles of the bridge were recorded, including measurement of the deck angle to link movement to stress development. All measurements were collected at 1000 Hz. By the end of the campaign, more than 2 terabytes of data were gathered. CT de Boer and Somni are now preparing these datasets for analysis, after which they will support fatigue modelling at Eindhoven University of Technology and contribute to the Digital Twin development at the University of Twente.

Building Reliability Through Measurement

Anton concluded his talk by emphasizing that reliable assessment begins with reliable measurements. The Van Hall Bridge campaign shows how SUBLIME’s scientific and modelling work relies on precise, carefully planned field activities carried out on real, operational structures. This combination of practical engineering and academic research helps advance the understanding of fatigue behavior in movable bridges and supports the broader goal of improving the long-term reliability of Dutch steel infrastructure.

Sheet Pile Corrosion Study Begins

The SUBLIME project is taking a major step forward in understanding how steel sheet piles age in real port conditions. In close collaboration with North Sea Port (NSP), TU Delft researcher Prasaanth Ravi Anusuyadevi is preparing the installation of a new field-testing structure that will allow long-term monitoring of corrosion processes on S355 steel.

Following recent discussions between TU Delft and NSP, both partners agreed to install a dedicated sample-carrying structure directly in the port. The design includes three identical frames, each hosting nine steel samples and each intended for different exposure durations: 3 months, 6 months and 1 year. The samples will be positioned at different depths along the waterline to capture how corrosion varies from splash zone to full immersion.

Smarter Cameras from Fewer Views — A Sparse-View Pose Estimation

How do you recreate a 3D scene using just a few pictures from different angles? That’s a challenge many fields face — from drone-based inspections to 3D mapping for remote sensing or structural health monitoring. Qingyu Xian, PhD researcher at the University of Twente, is tackling this challenge head-on in the SUBLIME project with a novel tool that’s already showing strong results: the T-Graph module.

Smarter Testing for Steel Bridges: How Few Tests Can Tell Us More

Many steel bridges across Europe are reaching the end of their intended service lives, raising critical questions about how to assess and extend their safe use. Within the SUBLIME program (“Sustainable and Reliable Macro Steel Infrastructures”), our mission is to ensure that these critical structures remain safe, sustainable, and serviceable for decades to come. One of the program’s key objectives is developing smarter assessment tools that help us better understand the condition of ageing steel — particularly when data is limited. That’s where the work of Elena Zancato, PhD researcher at Eindhoven University of Technology (TU/e), comes into focus.