As infrastructure across Europe ages, the maintenance of critical steel assets — like bridges, lock doors, and sheet pile walls — is becoming an increasingly urgent challenge. The SUBLIME project (SUstainaBle and reLIable Macro stEel infrastructures) aims to address this with an ambitious, multidisciplinary approach, combining structural health monitoring, predictive modeling, and data-driven governance strategies. A key part of this effort is the development of Digital Twins (DTs) — dynamic, virtual replicas of physical structures that can be used for real-time analysis and predictive maintenance.

On May 23, 2025, the SUBLIME consortium gathered for an online workshop to present the progress of Work Package 2, focused on Digital Twin development. The session featured an engaging and technically rich demonstration by Ali Sabzi Khoshraftar, an EngD researcher from the University of Twente, who unveiled the first prototype of the DT platform developed for bridge infrastructure.

Corrosion in Focus: A Shared Challenge

The meeting focused on two distinct regions: the North Sea Port, where sheet piles are over 20 years old and protected by sacrificial anodes, and PZH, where newer structures (around 6–7 years old) rely on Impressed Current Cathodic Protection (ICCP). In the first case, despite these cathodic protection systems, significant corrosion has been detected, especially in the low-water and tidal zones—areas due to suspected microbial induced activity. International case studies from the UK, Spain and Japan confirm that this issue is widespread.

Digital Twins for Smarter Infrastructure

The motivation behind the digital twin approach is compelling. Traditional inspection methods are manual, infrequent and often rely on subjective observations archived in static reports. In contrast, a digital twin provides a live, interactive and evolving model of the structure, built on real-time sensor input and capable of integrating advanced technologies like artificial intelligence (AI), virtual reality (VR), and augmented reality (AR).

Ali began his presentation with striking examples of recent bridge failures — such as the Pittsburgh bridge collapse — to illustrate the pressing need for more accurate, objective and data-rich approaches to maintenance. His prototype DT is designed to deliver precisely that: a streamlined, integrated environment where sensor data, structural models and user interfaces come together to inform engineering decisions.

A New Modelling Approach

A core ambition of the SUBLIME project is to develop predictive Digital Twins that integrate both structural models and data. During the meeting, researchers outlined a two-step modelling strategy: (1) translating corrosion into deformation and (2) assessing how deformation accelerates failure. This iterative method will rely on a Bayesian framework to manage uncertainties and perform simulations using a reduced set of key parameters. The ultimate goal is to better predict remaining service life and guide timely maintenance.

Inside the Prototype

Ali’s platform, built in C# and Windows Presentation Foundation (WPF), integrates a variety of components:

- Sensor Data: The system simulates real-time measurements from accelerometers mounted on a case study bridge in the Twente region of the Netherlands.

- 3D Visualization: A photogrammetric model of the bridge, constructed from nearly 400 drone images using open-source software (Meshroom), provides a visual reference for inspection.

- Analysis Modules: Python-based analysis tools (currently frequency analysis) are embedded and easily expandable.

- Immersive Inspection: A Unity-based VR module allows users to perform virtual bridge inspections in an immersive environment.

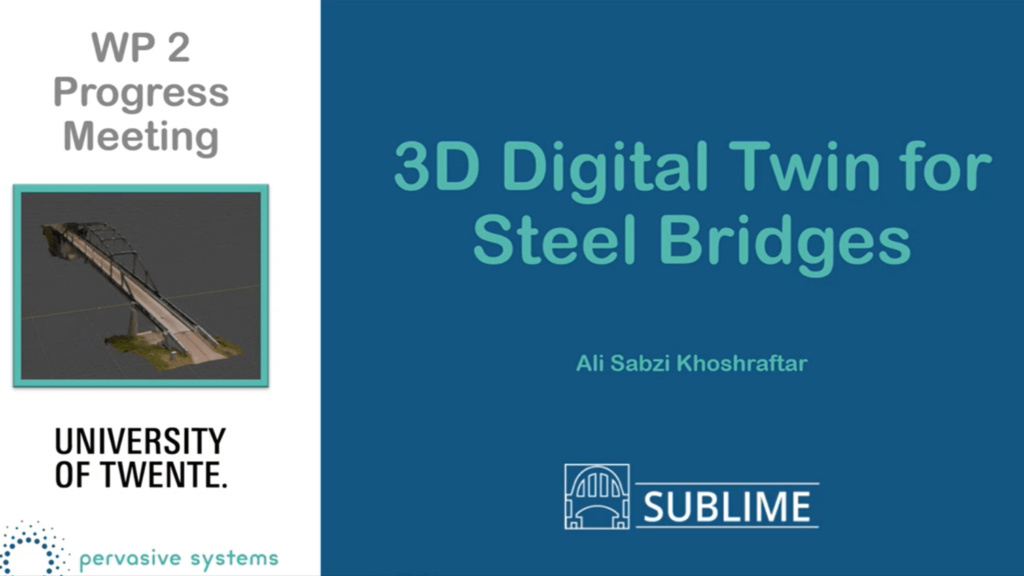

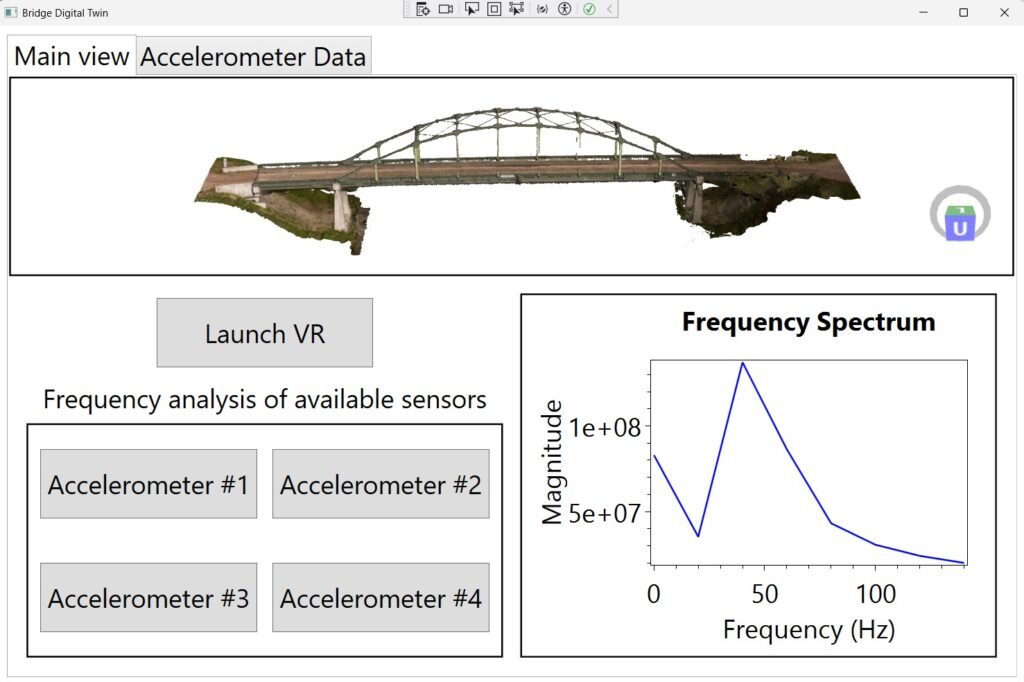

The platform includes two main tabs: one for structural overview and analysis (Figure 1), and another for live sensor monitoring (Figure 2). Users can interact with the 3D model, view real-time data, or launch the VR module for a more immersive inspection experience. Notably, the VR application requires a VR headset. However, the core platform can be used on any desktop system.

Figure 1. First GUI tab showing the interactive 3D model, VR button, and real-time frequency analysis [1]

Figure 2. Second GUI tab displaying real-time sensor feed and recent changes [1]

Looking to the Future

A valuable discussion followed the demonstration. One partner raised a thoughtful question about the usefulness of virtual reality, given the relatively limited accessibility and lower resolution of current VR headsets. Ali responded by emphasizing that hardware is evolving rapidly, with significant advancements in both consumer and professional-grade VR and AR devices expected within the next couple of years. Devices are becoming sharper, lighter and more affordable. Moreover, he stressed that this research is forward-looking — preparing for a future where immersive environments are standard tools in engineering practice. Just as 3D CAD models eventually replaced 2D blueprints, immersive twins may soon become mainstream in asset monitoring. Additionally, the VR application is just one layer. The real innovation lies in the platform’s flexibility — the ability to integrate Python-based AI modules, visualize multi-modal data, and potentially enable augmented reality (AR) overlays during on-site inspections. In this vision, an inspector could wear AR glasses to instantly view historical damage data, AI-flagged anomalies, or even live sensor feeds — all hands-free, and in context.

This prototype is a first step. The emphasis on VR is not only about current utility but also about positioning the SUBLIME platform at the frontier of technological innovation. VR is an enabler for more immersive, accurate inspections and it paves the way for on-site augmented reality (AR) use cases — where inspectors could access live data and AI-generated insights while physically present at the bridge.

A Platform for Collaboration and Iteration

While the current prototype already integrates some real-time data, visual interfaces and inspection modules, it is intended as a starting point. Ali was transparent that further development is needed before it can be considered a robust product ready for field deployment. Additional features under consideration include:

- More advanced AI-assisted defect detection

- Integration with real databases or sensor networks

- Enhanced user interface and data management tools

- Expanded VR/AR functionalities for field inspections

A simple user manual will be created to help interested users install and explore the platform independently. Ali also offered to prepare a developer-focused guide explaining how to customize key components, such as switching the 3D model or modifying the analysis modules — a particularly useful resource for partners wanting to build on the platform in their own research or applications.

What’s Next: A Hands-On Workshop in early 2026

Recognizing the value of direct engagement, the team think of organizing a follow-up, hands-on workshop in early 2026, once the platform has been further refined. In this session, each interested partner will have the opportunity to:

- Download and install the DT platform on their own computer;

- Explore the features and data modules independently;

- Receive step-by-step guidance from Ali and the development team;

- Provide real-time feedback and suggestions for improvement.

This interactive format will help users better understand the capabilities of the platform while also supporting its iterative development. It will also facilitate deeper integration into practical workflows at asset owners, engineering companies and inspection firms across the consortium.

CT de Boer Showcases SUBLIME Fieldwork at the 2025 M2i Conference

During the 2025 M2i Conference at Papendal, Anton Gorter of Civiele Technieken de Boer presented the progress of SUBLIME’s field monitoring work on the Van Hall Bridge in Amsterdam. His talk, “An on-site measurement campaign – it sounds so simple” highlighted the many practical steps and unforeseen challenges involved in collecting high-quality strain data on a historic movable steel bridge.

Sheet Pile Corrosion Study Begins

The SUBLIME project is taking a major step forward in understanding how steel sheet piles age in real port conditions. In close collaboration with North Sea Port (NSP), TU Delft researcher Prasaanth Ravi Anusuyadevi is preparing the installation of a new field-testing structure that will allow long-term monitoring of corrosion processes on S355 steel.

Following recent discussions between TU Delft and NSP, both partners agreed to install a dedicated sample-carrying structure directly in the port. The design includes three identical frames, each hosting nine steel samples and each intended for different exposure durations: 3 months, 6 months and 1 year. The samples will be positioned at different depths along the waterline to capture how corrosion varies from splash zone to full immersion.

Smarter Cameras from Fewer Views — A Sparse-View Pose Estimation

How do you recreate a 3D scene using just a few pictures from different angles? That’s a challenge many fields face — from drone-based inspections to 3D mapping for remote sensing or structural health monitoring. Qingyu Xian, PhD researcher at the University of Twente, is tackling this challenge head-on in the SUBLIME project with a novel tool that’s already showing strong results: the T-Graph module.